Design and Development

for Plagiocephaly Treatment

Overview

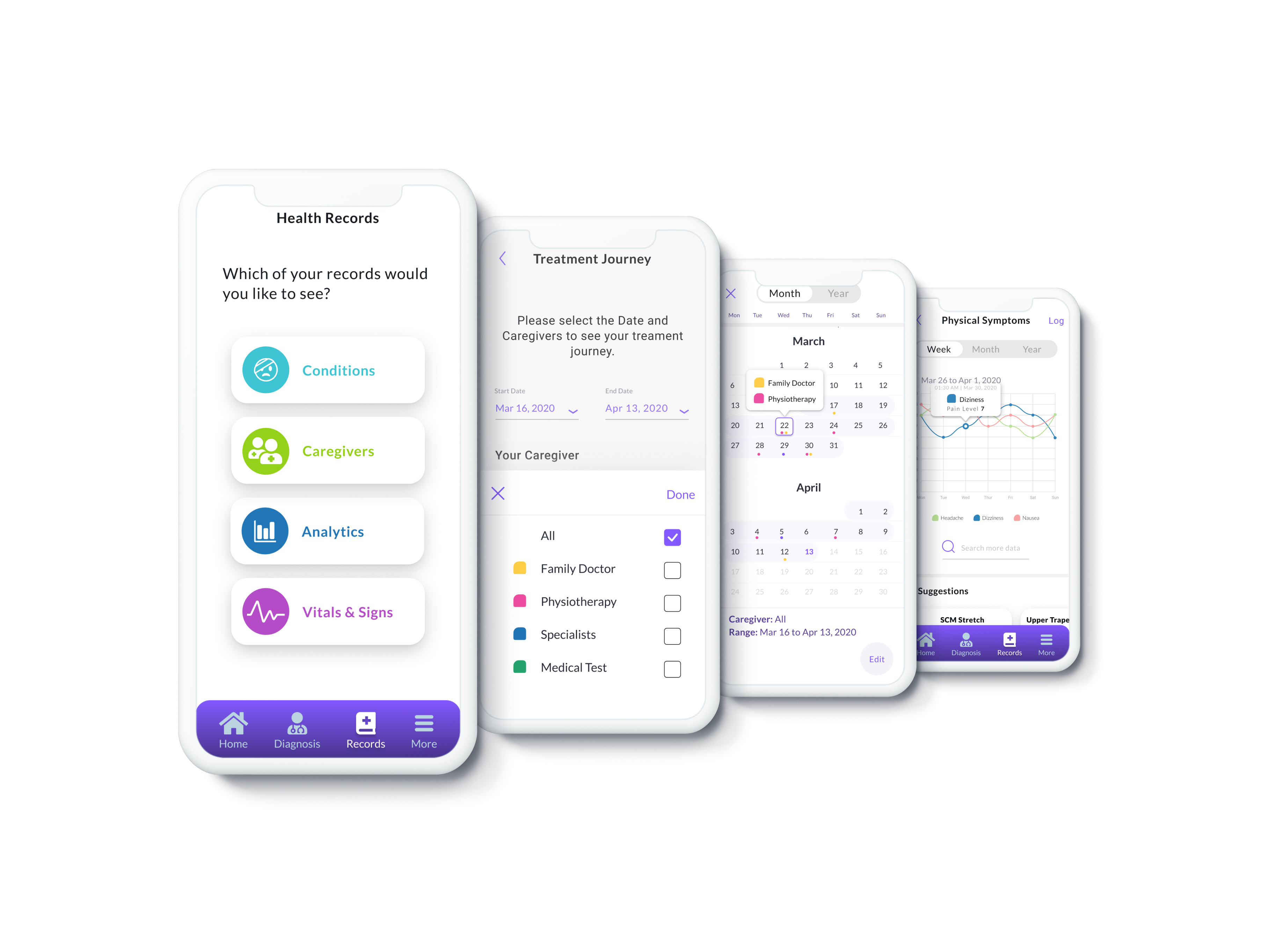

Objective: Improve the design of therapy helmets for infants with misshaped heads.

Client: HeadStart Medical LTD is a health engineering firm wholly committed to treating infants with plagiocephaly and other forms of cranial deformation.

My Role: As the research assistant at Emily Carr Living Lab, I lead this collaborative design project with agile approach during 3 months in 2017. This iterative process led to the design solutions, including form, function, material, weight as well as the user experience, including how to use, care and the treatment process follow up. Below is a list of design methods that I used in this project:

-> Survey

-> Interview

-> Market Research (SWOT)

-> Ideation (Brainstorming, Sketch, Affinity map)

-> Agile methodology (Lean UX)

-> User Testing

-> Prototype

-> 3D Visualization

-> 3D Print

Problem Area

Plagiocephaly is a condition that causes an infant's head to have a flat spot or be misshapen. This usually occurs when a baby's head develops a flat spot due to pressure on that area. Babies are vulnerable because their skull is soft and pliable when they're born. A recent study conducted in Calgary indicated 46 percent of babies head in Canada are misshapen. (CBC News, 2013). The therapy helmet's purpose is to alleviate pressure from the flat spots, allowing the skull to grow into the spaces provided inside the helmet.

Product Problems and Customer Requests

From the client point of view the current product has two significant problems:

To address these issues, Head Start asked for redesigning their current product by considering the following two factors:

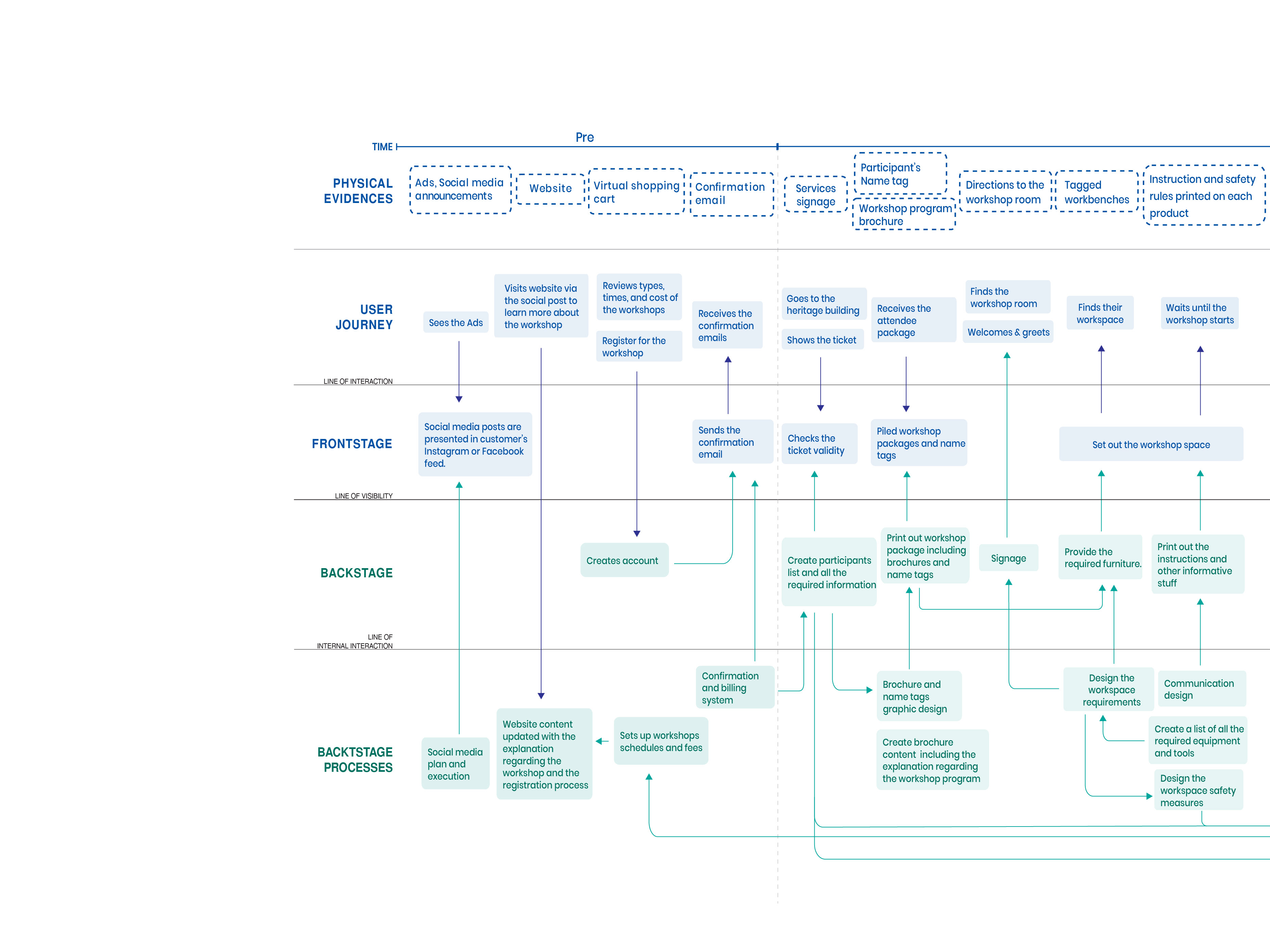

Research Approach

In this project, I provided the client with my findings from the secondary and primary research, interviews and observations, mood-boards, market analysis, brainstorming and sketches from ideation phases, prototypes and finalized CAD modeling of the selected solutions. Almost anything that was required in producing the new helmet.

Agile Methodology

This project happened in a short period of time from January to April 2017. Basically, I worked with agile methodology in all design phases; from research and ideation to prototype and user testing. Firstly, I reviewed the existing secondary research that company had conducted by that time to export required information and familiarizing myself with this particular area. Then, I educated the client regarding the design process, and agile development that I was planning in order to generate the best solutions quickly.

Through the questionnaires and interviews with Headstart CEO and also observing and interviewing with their medical team (both doctors and patients) we came up with a renewed problem statement after a few sessions. Every session even after the first meeting, I allocated a part of our discussions to collaborating ideation and exchanging ideas freely and frequently.

Lean UX canvas provided us with great beneficial assumptions, such as what problems the product has, what strategies the business has to be addressing, who the target user is and so forth.

About the Client

Design Requirement Specifications

By analyzing the assumptions and information gathered from the interviews and observations, we came up with a list of desired product attributes.

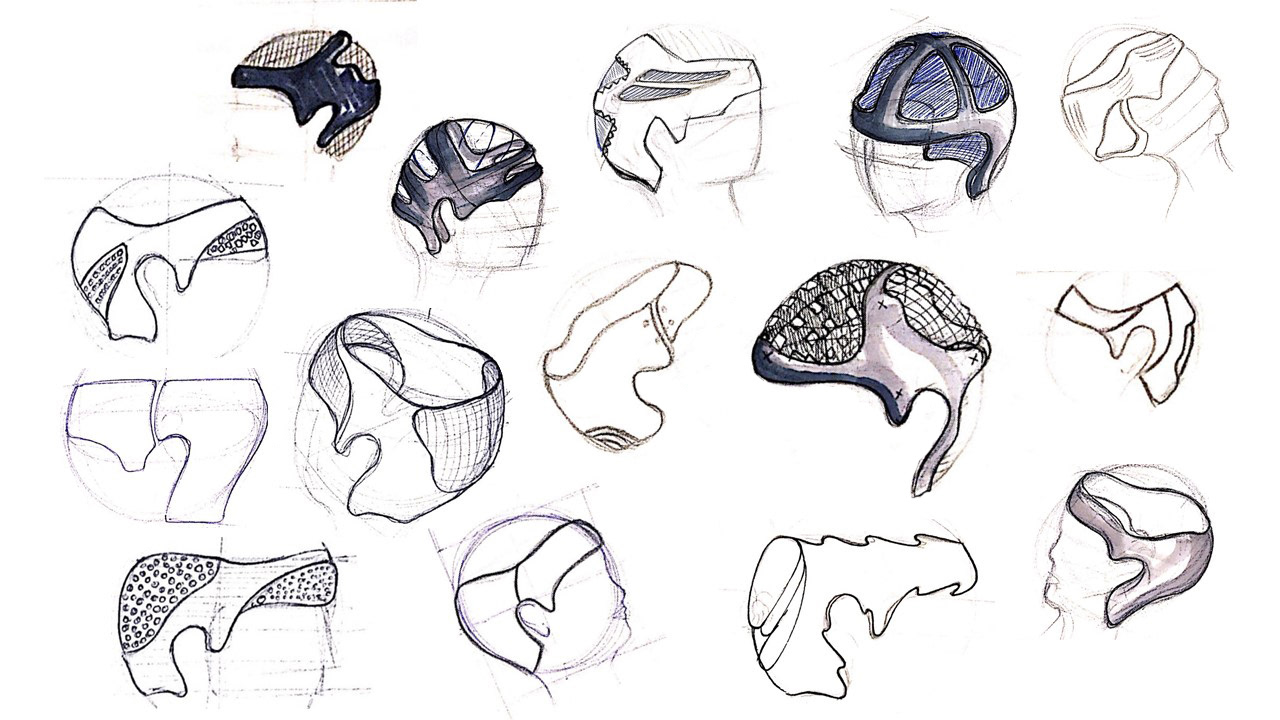

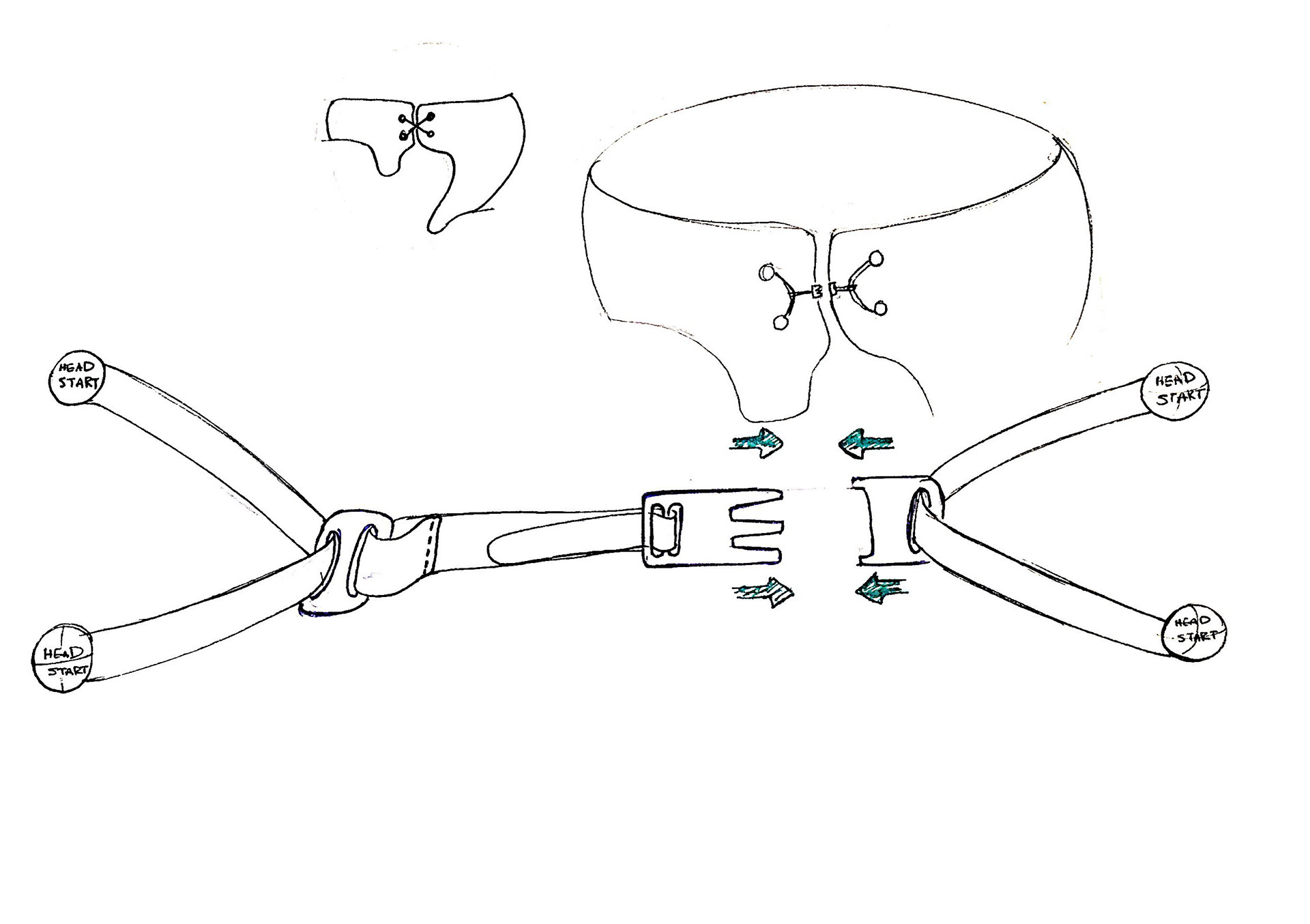

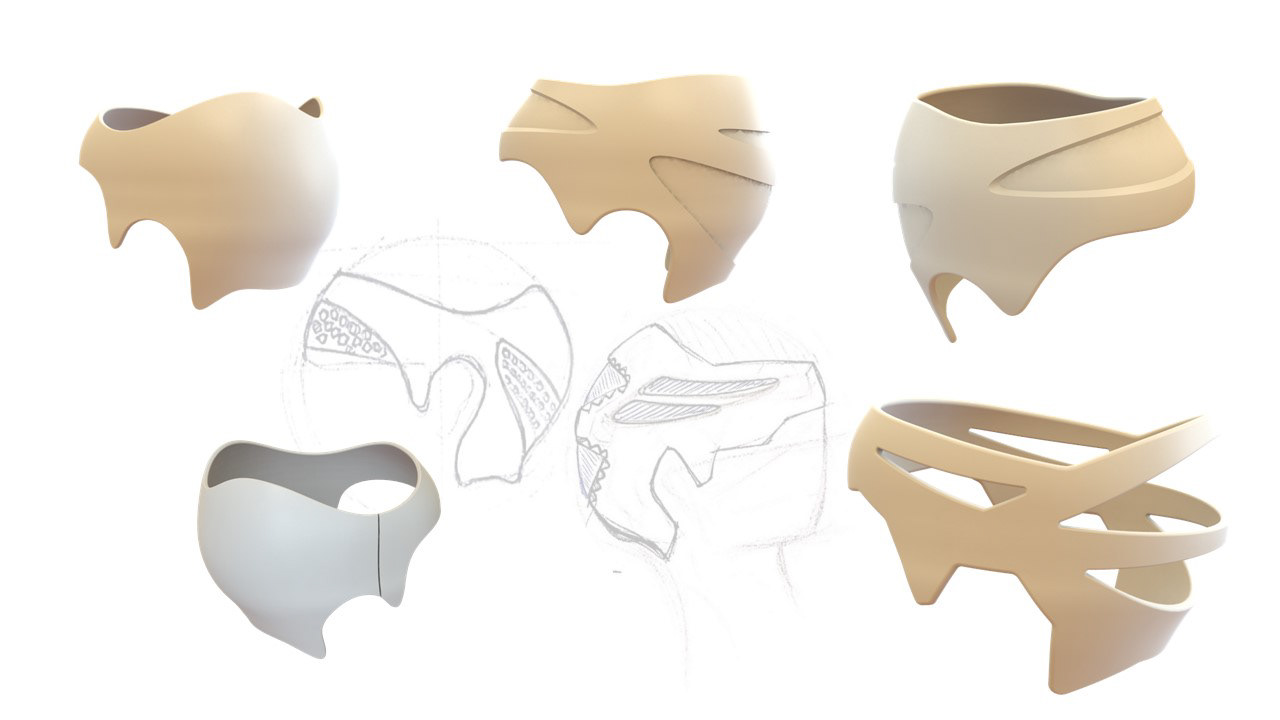

Ideation and Concept Development

HeadStart was looking for wide varieties of ideas. I was asked to think out of the box and come up with as many ideas as I could. Brainstorming sessions were conducted in our weekly meetings with the client and also Living Lab team members. After each meeting beside the other actions of the project, I had sketched the selected concepts/ideas, or made either digital or physical low-fed 3D prototypes to test our assumptions. This led to a list of 100 ideas. Clustering and selecting ideas by considering the design requirements happened next. Thanks to the client's 3D Printing facilities, we were able to bring our solutions to the reality very fast to test them as much as required.

Insights about challenges the babies have, insufficient accuracy of their current product guided me to design 3D models of the product in Rhino to 3D print more than 40 physical prototypes to understand how the redesigned product could best address the issues. Learnings from those prototypes, usability tests, interviews and hours of discussions with the client helped me to define the form, material, as well as the steps parents need to follow up the treatment. Everything that they needed in producing the redesigned product.